Control valves used for steam heating coils are typically – Control valves are crucial components in steam heating coil systems, responsible for regulating the flow of steam and maintaining desired temperatures. This article delves into the various types of control valves employed in these systems, their selection criteria, installation and maintenance considerations, common troubleshooting issues, and advanced control strategies for optimizing performance.

As we explore the intricacies of control valves for steam heating coils, we uncover the factors that influence their selection, such as system pressure, temperature, and flow rate. We also provide practical guidance on proper installation and maintenance procedures to ensure longevity and optimal operation.

Control Valves for Steam Heating Coils: Control Valves Used For Steam Heating Coils Are Typically

Control valves play a crucial role in regulating the flow of steam in steam heating coils, ensuring optimal system performance and energy efficiency. Various types of control valves are employed in these applications, each with unique characteristics and advantages.

Types of Control Valves Used for Steam Heating Coils

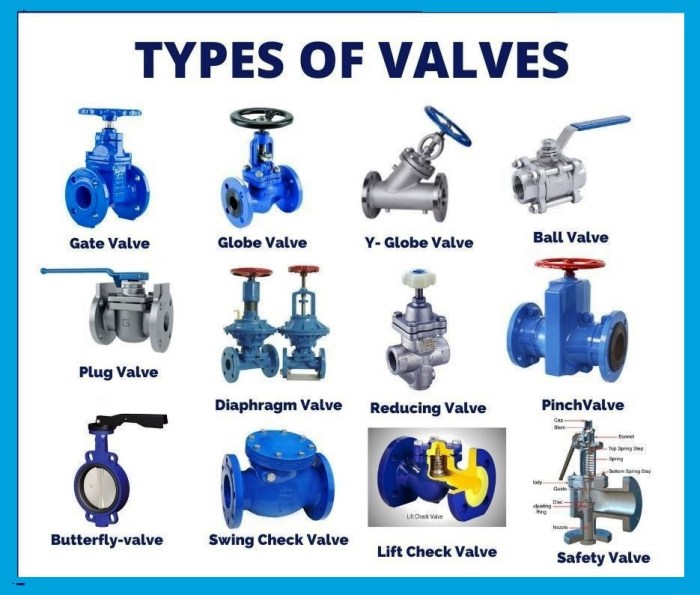

Commonly used control valve types for steam heating coils include:

- Globe Valves:Linear motion valves that provide precise flow control and tight shutoff. However, they can experience high-pressure drop and noise.

- Ball Valves:Rotary motion valves that offer low-pressure drop and quick shutoff. However, they may not provide as precise flow control as globe valves.

- Butterfly Valves:Rotary motion valves with a large flow capacity and low-pressure drop. They are suitable for large-diameter piping systems.

- Diaphragm Valves:Actuated valves that use a diaphragm to control flow. They provide high-pressure drop and are suitable for applications with frequent cycling.

Selection Criteria for Control Valves

When selecting control valves for steam heating coils, several key factors must be considered:

- System Pressure and Temperature:Valves must be rated for the maximum pressure and temperature of the steam system.

- Flow Rate:Valves must have sufficient flow capacity to meet the heating demand.

- Control Accuracy:Valves must provide precise flow control to maintain desired coil temperatures.

- Maintenance Considerations:Valves should be easy to maintain and repair to minimize downtime.

Installation and Maintenance Considerations

Proper installation and maintenance are crucial for optimal control valve performance:

- Valve Sizing:Valves should be sized correctly to avoid excessive pressure drop or flow limitations.

- Piping Connections:Piping should be aligned properly to avoid strain on the valve body.

- Regular Maintenance:Valves should be inspected and serviced regularly to ensure proper operation and prevent failures.

Troubleshooting Common Issues, Control valves used for steam heating coils are typically

Common problems encountered with control valves in steam heating coils include:

- Leaking:Caused by worn seals, damaged seats, or incorrect installation.

- Sticking:Caused by corrosion, debris, or misalignment.

- Flow Control Issues:Caused by incorrect valve sizing, damaged actuators, or calibration problems.

Advanced Control Strategies

Advanced control strategies can optimize control valve performance in steam heating coils:

- PID Controllers:Proportional-integral-derivative controllers provide precise temperature control by adjusting valve position based on feedback.

- Cascade Control:A combination of two or more control loops to improve system stability and response time.

- Model Predictive Control:Uses a mathematical model to predict future system behavior and adjust valve position accordingly.

Helpful Answers

What are the most common types of control valves used in steam heating coils?

The most common types include globe valves, butterfly valves, and ball valves.

How do I select the right control valve for my steam heating coil system?

Consider factors such as system pressure, temperature, flow rate, and valve characteristics.

What are some common troubleshooting issues with control valves in steam heating coils?

Common issues include valve leakage, cavitation, and sticking.